Advanced Loading Solutions

Rollerbed Systems LLC is where innovation meets reliability. Discover a comprehensive range of advanced loading solutions to enhance efficiency and optimize logistics operations. Each product embodies our commitment to quality and performance, from pneumatic roller tracks to specialized loading systems.

Pneumatic Roller Track

Since its inception in the 1970s, the use of air or hydraulic power to lift rollers for material handling has evolved significantly. Today, this technology offers a safe, efficient, and cost-effective method for transporting heavy and large unitized loads within the transportation industry.

Features Made in the USA

Powered Cargo Rollers

The Rollerbed Systems LLC Powered Cargo Roller unit represents a state-of-the-art solution for handling heavy loads. This self-contained, electrically powered drive roller features a durable polyurethane covering and operates seamlessly with vehicle onboard electrical systems of 12 or 24 volts DC. Utilizing low-pressure air, the roller effortlessly lifts against the underside of the load, ensuring secure movement. This system can load or unload a 53- foot trailer in as little as 90 seconds.

Benefits

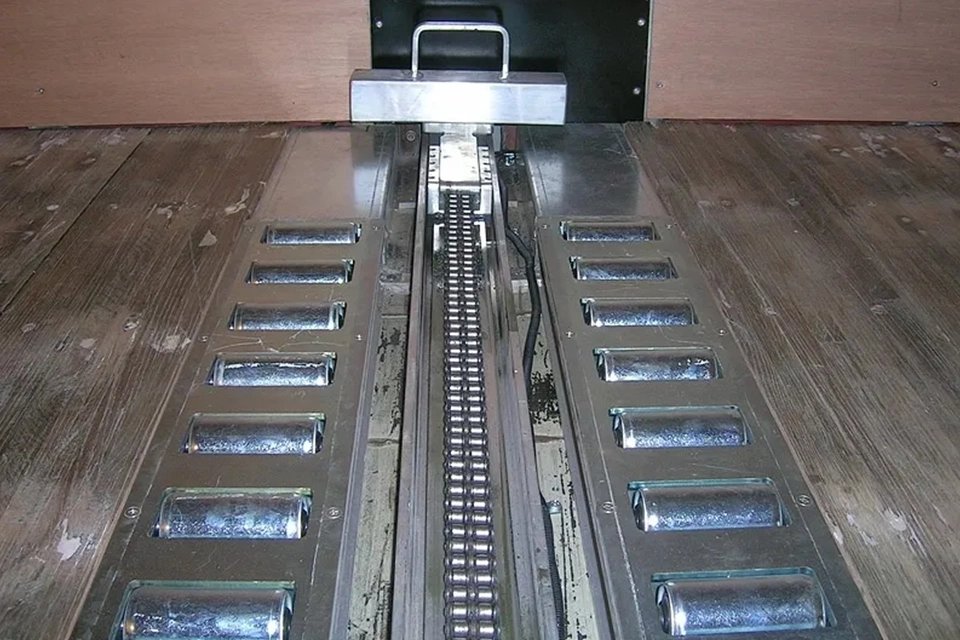

Powered Slipchain

The Slipchain method revolutionizes load handling by extending the pneumatic roller track concept to chain conveyors. This advancement allows for safely and precisely moving palletized loads to their designated positions. Supported by minimal air pressure, an endless chain easily transports substantial cargo. A 53-foot trailer can be loaded or offloaded in as little as 90 seconds.

How It Helps

Powered T-Bar

The T-Bar system offers a highly efficient method for unloading entire pallet loads from a vehicle in one swift motion. A single track of duplex chain runs along the vehicle's center, with the T-Bar puller bar attached to pull the entire load onto an unloading dock or conveyor system. When paired with Rollerbed Systems LLC's pneumatic roller track, this system can unload a 53-foot trailer in under two minutes, significantly reducing turnaround times.

What to Expect

Spare Parts

At Rollerbed Systems LLC, we maintain a robust inventory of parts for pneumatic roller systems and powered systems. When you contact us before 12 PM EST, we ensure same-day shipping of your parts. As a domestic manufacturer, we guarantee OEM components identical to those originally used in your system. Additionally, we provide roller track refurbishment and upgrade kits to enhance system longevity and performance.

Accessible Resources

Explore our downloads page for a detailed list of common spare parts and information on roller track refurbishment kits. Our commitment is to support your operational needs with reliable components and comprehensive service solutions. Reach out now to discuss your specific requirements and benefit from our expertise in enhancing efficiency and reliability.